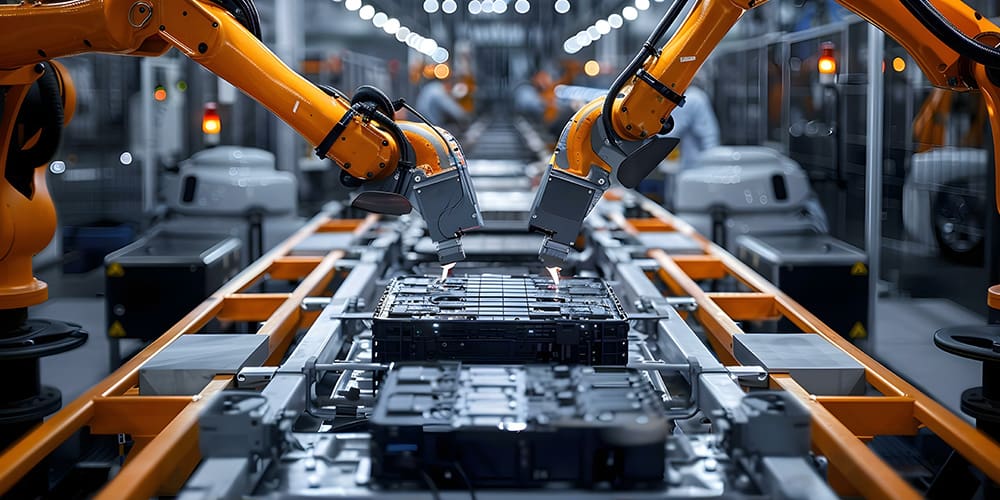

With the growing push for sustainability and efficiency, the electrification of industrial vehicles is not just a technological milestone but a necessity. As electric vehicles (EVs) transform transportation and expand their reach into various industrial sectors, the need for robust and reliable battery systems becomes more critical.

Revolutionizing Industrial Battery Technology

Industrial batteries, especially those used in EVs, are subject to critical conditions and demanding requirements. These batteries must maintain high performance for long periods of time, often in environments where conditions can be harsh. The efficiency of the battery is greatly impaired if it cannot effectively handle the heat generated during operation. Improper thermal management can lead to performance degradation, safety hazards such as thermal runaway and ultimately reduced life.

In addition, EV batteries need to demonstrate impressive durability and reliability to withstand the mechanical stresses and vibrations present in industrial applications. This is where the heat-retaining structural adhesive plays an important role, ensuring that the battery components remain securely sealed while providing for efficient heat dissipation.

Thermal Management and Durability

Improper thermal handling of batteries can lead to performance degradation and safety hazards. Parker's CoolTherm® TC-2002, a two-part adhesive system, is designed for maximum thermal flexibility. It improves thermal insulation, reduces the risk of overheating and promotes longer battery life. The strong mechanical adhesive bond maintains structural integrity, which is important in industrial applications where batteries are subject to constant movement and vibration. In addition, properties such as flame reduction and electrical isolation make CoolTherm TC-2002 the ideal solution for safety and reliable operation.

Real World Industrial Applications

In real-world situations, Parker's CoolTherm thermal management materials have helped improve the performance and reliability of EV batteries used in sectors such as construction, mining, agriculture and transportation. An electric forklift manufacturer that integrates CoolTherm TC-2002 into their battery design, for example, will benefit from improved heat management and structural support. This integration not only extends battery life but also contributes to the forklift's energy efficiency and operational safety.

Emerging Markets Drive Advanced Battery Demand

Outside of mainstream automotive applications, several emerging non-automotive EV markets are rapidly adopting advanced battery technology. Each sector presents unique needs and opportunities for growth.

- Warehouse Revolution: The warehouse industry, which includes electric forklifts, personnel carriers and stock chasers, is rapidly transitioning from nickel battery and propane powertrains to lithium-ion battery powertrains. Lithium-ion battery technology has allowed more energy use compared to propane or natural gas but is also driving the shift from nickel batteries to Li-ion. The electric storage equipment market is expected to grow significantly due to increased demand from the e-commerce industry, increasing focus on sustainability and improvements in battery technology.

- Transforming Transportation: Trucks and Buses: Electric trucks and buses are booming, fueled by technological innovation and stricter emissions regulations. Expected cost parity with diesel trucks and buses is accelerating their adoption, further supported by battery developments that promise improved performance and reduced environmental impact.

- Electrical installation in the construction industry: The electrification of construction equipment is on the rise, with electrical equipment requiring batteries that can withstand harsh environments. The market for batteries for heavy-duty electric vehicles, including those used in construction applications, is responding to these demands with robust battery designs and is expected to experience significant growth, with forecasts showing a Compound Annual Growth Rate (CAGR) of between 10% and 15% over the next decade. This growth is driven by increased environmental regulations, rising fuel costs and advances in battery technology that can better match the building requirements. Documented benefits also exist in reduced pollution and worker hazards in poorly ventilated construction sites. In addition, noise-related regulations within the city regulate the hours of operation of high-speed diesel generators, but these restrictions may not apply to other quieter electric systems.

- The rise of electric motorcycles: Globally, the electric motorcycle market is experiencing strong growth, with projections showing an increase from a $30 billion market to more than $140 billion by 2030. of this field.

- Marine and Aerospace Innovations: The marine and aerospace industries are tapping into advanced battery technology, with market projections showing significant growth. These sectors focus on developing batteries that address challenges such as corrosion resistance and weight constraints, often involving hybrid systems and renewable energy solutions. The global marine battery market alone is expected to expand from $1.3 billion in 2024 to $5.4 billion in 2032.

Challenges and Solutions in Non-Automotive EV Battery Development

In the field of non-motorized electric vehicles (EVs), industrial batteries face unique challenges that are important for their performance and safety. For one, effective thermal management is essential to prevent overheating and ensure reliability during charge and discharge cycles. Additionally, achieving weight reduction without compromising battery performance is critical to improving vehicle performance.

The need for strong sealing solutions is equally important, as it protects the battery enclosures from environmental factors and maintains operational integrity. In addition, improving the durability and longevity of these batteries is essential to withstand the demands and harsh conditions they face. Addressing these challenges is critical to improving the efficiency and safety of industrial batteries in non-automotive EV applications.

Parker uses his expertise in advanced materials and technologies to address the major challenges battery manufacturers face in the non-automotive EV sector. By using advanced thermal management solutions, optimal heat dissipation is achieved, preventing overheating and improving overall battery reliability.

Additionally, encapsulants and potting compounds, including the CoolTherm portfolio, are designed to improve the durability and longevity of battery packs by providing stronger protection and heat management. Parker tailors these solutions to meet the specific needs of non-automotive EV applications, ensuring optimal battery performance and reducing downtime.

Taking Opportunities in a Dynamic Market

The demand for advanced battery technology will increase as industries continue to innovate. The industrial battery market is showing a broad commitment to sustainability and efficiency, with sectors such as construction, transportation and logistics leading the way. As these industries continue to innovate, so does Parker. With complementary solutions, Parker continues to not only meet but exceed the specific needs of each industry. Parker invites you to explore how their advanced battery technology can power your operations and drive success in these changing markets.

Incorporating thermal adhesives, such as Parker's CoolTherm TC-2002, into battery systems underscores the strides being made to improve performance and safety. By handling hot loads effectively, these attachments extend battery life, improve safety and ensure consistent performance even in challenging conditions.

For businesses aiming to capitalize on these market opportunities, understanding the evolving landscape and role of advanced battery technology is essential. Parker's solutions provide a path to success, enabling cross-functional operations with technologies designed to meet specific industry needs.

The electrification of industrial vehicles and the rise of non-automotive EV markets herald a new era of battery technology. By addressing key challenges in thermal management and sustainability, as well as exploring emerging markets, industries can leverage these developments to drive growth and innovation.

For more information on how Parker's advanced technology can transform battery systems in your industry, visit their website or contact their team to explore the latest in thermal adhesives and other advanced solutions.